|

|

|

|

70T Excavator

Sleeve Pressing Machine 220V |

|

|

|

|

|

|

|

|

Product

Overview |

|

The excavator sleeve pressing

machine is a special device for pressing, assembling and disassembling

shaft sleeves of various construction equipment, can be widely applied

to the industries of machinery manufacturing, machinery maintenance and

repair, assembling and so on. The shaft sleeves can be accurately

assembled and disassembled through the pressing force, and the

assembling tightness and reliability are ensured. The bidirectional

hydraulic device is adopted to reduce oil circuits, operation is

flexible and convenient, and the service life is long. |

|

Product

Parameters |

|

Product Name |

70T Excavator sleeve pressing machine |

|

Rated voltage |

220V Single-phase electricity |

|

Rated power |

1500W |

|

Pressure sleeve range |

<120mm/4.72in |

|

Screw diameter |

50mm/1.96in |

|

Screw length |

1000mm/39.37in |

|

Cylinder stroke |

100mm/3.937in |

|

Operating pressure |

0-63Mpa |

|

Pump station volume |

16L |

|

Note: |

|

1. There

will be a small error in manual measurement. |

|

2. The product pump station is

equipped with a plug. |

|

3. The tank should be filled with

hydraulic oil, and then the machine can be powered on to start,

otherwise the pump station will be damaged and the user needs to

be responsible for the consequence. |

|

4. The user needs to add #46 or

#68 anti-wear hydraulic oil to the pump station. |

|

|

|

Product

Features |

|

|

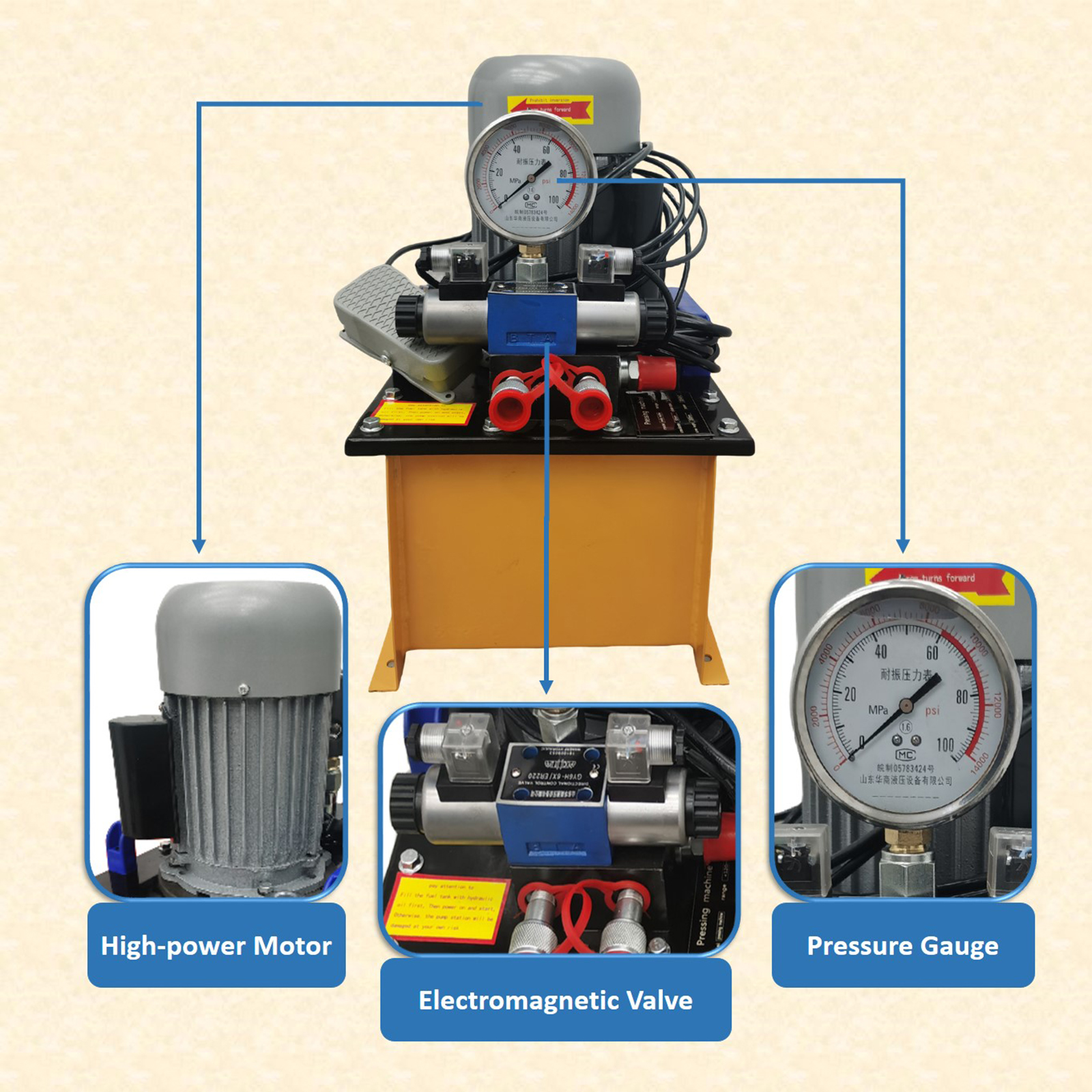

High-power Motor

The sleeve pressing machine is equipped with a 1500W high-power

motor which can provide sufficient power for sleeve pressing

operation. Start and stop are quick, high temperature resistance

is good, the production efficiency can be improved. The motor is

simple in structure and low in fault rate and suitable for the

industrial environment.

|

|

Electromagnetic Valve

As a key part, the electromagnetic valve can have a direct

influence on the response speed, stability and degree of

automation. It can achieve a quick response and high-precision

control and have high reliability, long service life and low

power consumption. Energy saving and high efficiency are

achieved, and the dynamic control over the pressing force can be

achieved.

|

|

Pressure Gauge

The anti-vibration pressure gauge is designed for the sleeve

pressing machine, the system pressure can be monitored

accurately and displayed dynamically, and it can ensure that the

pressing force can meet the technological requirement. The

anti-vibration design is adopted, so the safety and the

anti-interference are greatly improved.

|

|

|

|

Liquid Level Meter

The liquid level meter is mainly used for monitoring the oil

liquid in the system, ensuring stable running of the machine and

avoiding faults caused by oil shortage. It achieves real-time

monitoring and preventive maintenance, the liquid level can be

displayed accurately, clearly and visibly, and the fault rate

can be greatly reduced.

|

|

Oil

Filling Hole

The machine is equipped with an oil filling hole for equipment

maintenance, #46 or #68 anti-wear hydraulic oil can be added

through the oil filling hole, the friction coefficient of moving

parts can be reduced, and the contact wear can be avoided. The

operating stability can be improved, and the locating accuracy

of the sleeve pressing machine can be kept.

|

|

Foot

Pedal

The foot pedal is crafted for the sleeve pressing machine, the

convenient and safety control move is provided for the operator,

double hands can be liberated, the assembling accuracy can be

remarkably improved, the operating safety can also be enhanced,

and the foot pedal control mode is especially suitable for the

precision pressing application field.

|

|

|

|

Hollow Cylinder

The thickened hollow cylinder has the structural advantage of

the hollow design, the space is effectively saved, and it is

especially suitable for the narrow or complex working

conditions. The pressure distribution is uniform, deformation or

damage of the workpiece can be avoided, and controllability and

reliability are high.

|

|

Locating Sleeve

The taper locating sleeve is made of high-strength materials,

can evenly disperse the pressure, avoids the local stress

concentration and protects the workpiece. It can achieve high

precision positioning and alignment, is convenient to install

and disassemble and can be used repeatedly. It can adapt to

various working conditions.

|

|

Oil

Pipes

The long oil pipes are matched with the pump station, the high

pressure resistance and pulse resistance are high, and the

fatigue breakage risk caused by pressure fluctuation can be

reduced. The oil pipes are flexible and leakproof, convenient to

install and resistant to hydraulic oil and corrosion. Good

sealing performance is achieved.

|

|

1. High working efficiency, a

1500W motor, high power, high temperature resistance, stable operation

and long working time.

2. Quick response, high-precision dynamic control and low power

consumption.

3. Real-time monitoring and display of the pressure, good vibration

resistance and interference resistance.

4. Clearly and accurately display the liquid level, and reduce the fault

rate.

5. Convenient filling of hydraulic oil, low friction coefficient and

high operating accuracy and stability.

6. Liberate double hands, reduce the labor intensity, improve the

operating safety and ensure that the shaft sleeves are intact.

|

|

Operation Method |

1. Before operation, carefully check the

pressure oil circuit, transmission device and hydraulic pressure, and

ensure that the equipment is intact before starting.

2. At least two operators are required to operate the machine

cooperatively, and it is prohibited to work alone.

3. Before pressing the sleeve, the flange sleeve and the core must be

aligned.

4. If it is necessary to use a rod when pressing the sleeve, the rod

must be aligned with the core to prevent slipping and injury.

5. When pressing the sleeve, no one is allowed to stand directly in

front of the sleeve, the operators can only stand on the side of the

core and keep 1.0m away from the core.

6. After pressing the sleeve, move the core and flange sleeve away from

the operation area.

7. After the operation is completed, turn off the power supply and

organize the site.

|

|

Application |

|

As a professional pressing

device, the sleeve pressing machine can cooperate with the

electromagnetic foot pedal switch pump to complete assembly, disassembly

and replacement of shaft sleeves and can be widely used in multiple

industries, such as the highway construction industry, the railway

construction industry, the bridge construction industry and the

shipbuilding industry. |

|

|

Product

Display |

|

|

|

|

|

Item Number (022492):

1 x 70T Excavator Sleeve Pressing Machine 220V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|