|

|

新建网页 1

|

|

| The linear vibrating screen is specially

designed for large output. It can accurately screen and classify

materials and improve working efficiency.

The body part is equipped with a top cover,

which can reduce dust during operation.

|

|

Introduction: |

| The new high-efficiency screening equipment

has a screen moving trajectory that is approximately straight. This

sieve machine has simple structure, large screening capacity, low

energy consumption and easy maintenance. It is widely used in

mining, coal, electric power, metallurgy, building materials, fire

resistance and other industries for large block materials and medium

and small granular materials.

●The

linear vibrating screen has the advantages of small volume, light

weight, simple structure, convenient installation, easy operation

and maintenance.

●The

linear vibrating screen has low energy consumption and high

efficiency.

●The

screening accuracy of linear vibrating screen is high.

●Linear

vibrating screen parameters reasonable, stable performance.

●We

also provide other sizes of screen, if you need to contact us.

|

|

Working principle: |

|

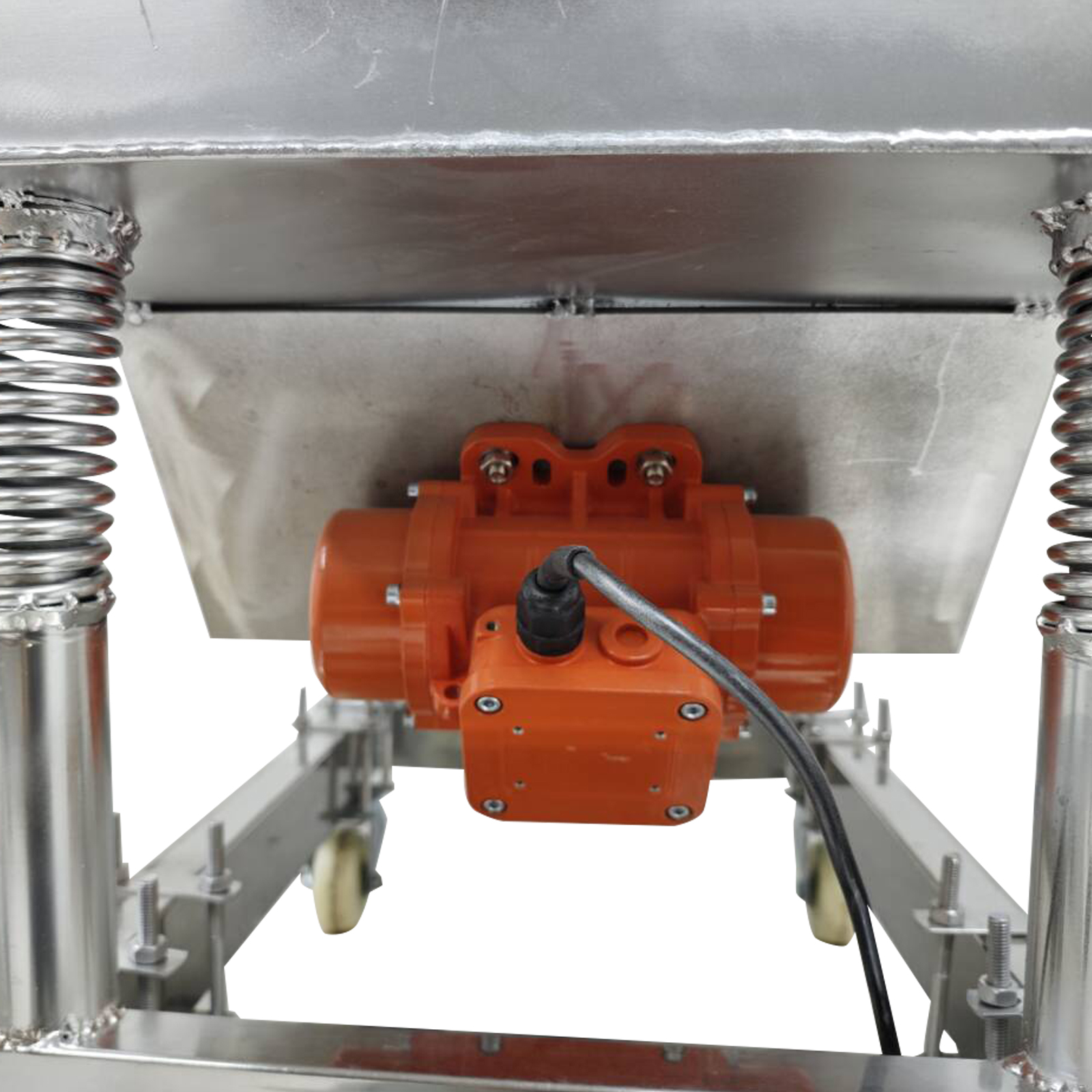

The screen box relies on

the vibrating motor to rotate in the opposite direction

simultaneously so that the whole screen machine supported on the

damper vibrates in a straight line. After the material falls into

the screen box from the feeding end, it quickly moves, loosens and

sifts through the screen to complete the screening operation.

This machine is composed

of sieve box, Machine top cover, vibration motor, vibration damping

system and chassis. The sieve box is composed of a sieve frame, a

sieve plate, a lining plate. This sieve machine adopts

high-performance, high-life vibration motor.

The machine is equipped with high-quality

stainless steel baffles that can adjust the discharge speed.

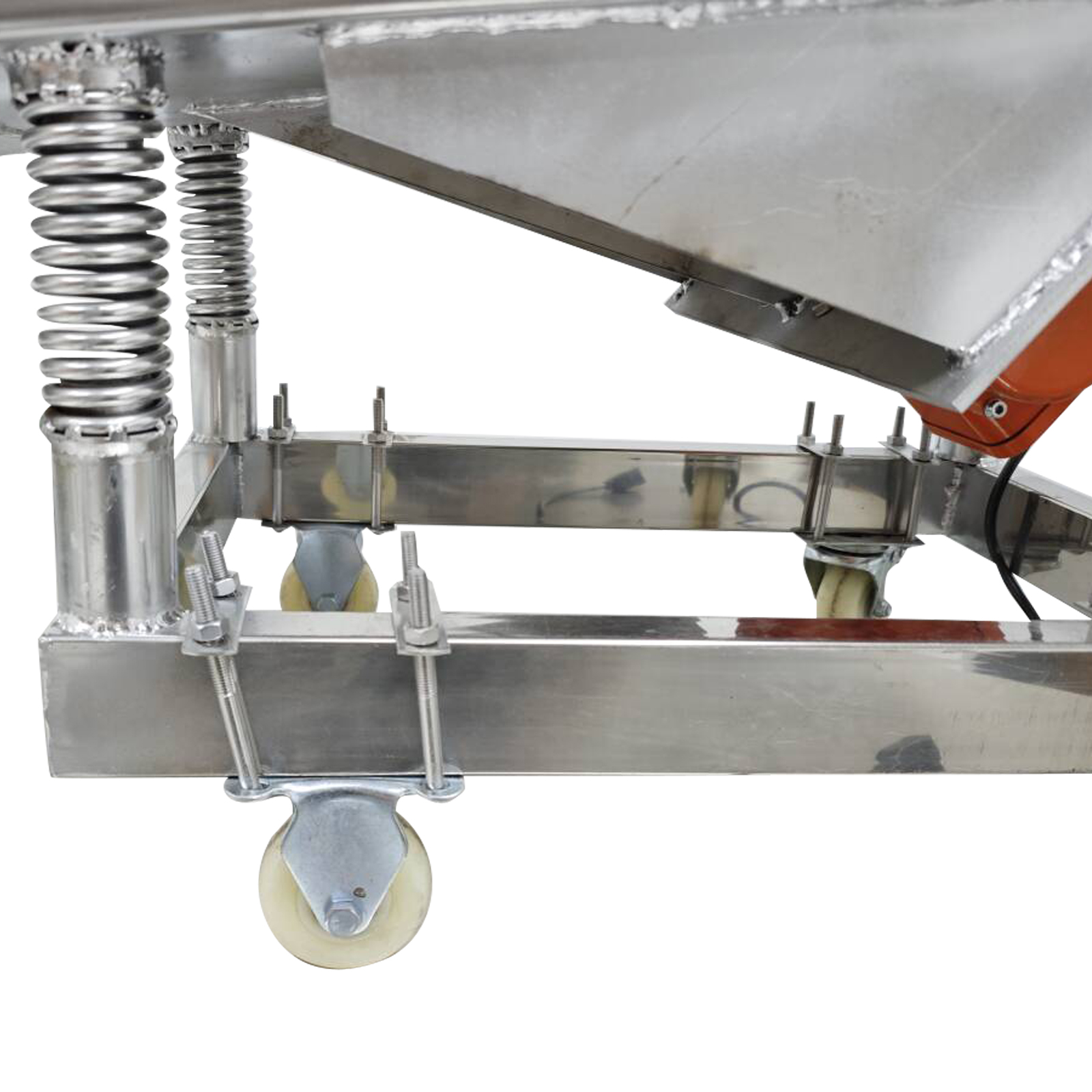

The vibration damping system consists of a

rubber spring and a clamp, a support base and the like. The chassis

consists of a silo and a chassis.

|

|

Product information |

|

Parameter:

| Material |

High quality stainless steel |

| Voltage |

110V |

| Power |

150W |

| Machine size |

39.37*19.49*25.98" |

| Size of feed port |

19.49*10.63" |

| Mesh size |

3mm |

| Mesh shape |

Round Hole |

|

|

|

Use Maintenance |

|

●Before

use, check all parts and accessories to ensure that the installation

is correct before power.

●The

vibrating parts of the machine shall not be connected with or in

contact with any object outside the machine while the machine is in

operation.

●When the

material is fed, it should be fed in the direction of the whole

width of the screen at the feed inlet to ensure the even

distribution of the material on the screen surface.

●When the

material falls, there should be no big impact, so as not to damage

the screen.

●No retained

material shall be found on the screen surface before starting or

stopping the machine.

●If there is

abnormal sound during the operation of the equipment, it should be

immediately shut down to check, after troubleshooting can boot. |

|

Details: |

High-quality motor material

advancement technology, faster material discharge, finer screening,

capable of continuous operation for 8-9 hours. |

|

Solid stainless steel trim,

durable and sturdy.

Tighten the fixing bolts during

use to secure the screen and pressure strip.

|

| Size of feed port:19.49*10.63"

Can be put into a one-time around 44.1LBS (20

kg) of material.

|

| The bottom wheels are adjustable, and you

can change the installation position of the wheels as needed.

|

| Two-stage outlet, the

classification of materials can be automatically excluded, saving

time and labor. Size of first stage

discharge port:5.12"

Size of secondary discharge port:5.91"

|

| The machine is equipped with high-quality

stainless steel baffles that can adjust the discharge speed.

|

| Without installing the baffle plate, the

sinking speed of the material cannot be adjusted.

|

| Linear vibrating screen is widely used in

chemical industry, plastics, metallurgy, glass, building materials,

fertilizer, ceramics and other industries.we also provide other

sizes of screen mesh, if you need, please contact us. |

|

Using steps |

| Check each part of the machine:

Install bottom wheels before use.

Check the machine base, especially the screw of the motor, if it is

loose, it needs to be tightened before use.

Install screen and place stainless steel batten.

Install the top cover and tighten the 4 stainless steel bolts. The

screen must be fixed to prevent damage caused by loose operation of

the machine.

Clean the screen in time after stopping work. |

|

|

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours

in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on

the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the

consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical

support from us with low cost. |

|