|

110V Steel Roller Thermal

Laminator With Slitting Cutter |

|

|

|

|

|

|

|

You can use the steel roll

laminator for thermal laminating and cold laminating operation. |

|

The steel roller thermal

laminator is designed for high-quality clear lamination of your prints,

presentations, menus, documents, book covers, photos and other visual

aids. It can do single-sided or dual-sided laminating with 0-8mm thick

films. The high-quality hard chromium plating rollers can evenly

distribute the heat so that high-quality lamination can be ensured. It

can be operated automatically or controlled through the foot control

switch. It is an excellent laminating machine for print shops, graphics

studio and professional offices. |

|

|

Product

Parameters: |

|

Heating Method: Steel roller

internal heating |

|

Working Speed: Steplessly

Adjustable 3-16ft(1-5M) per minute |

|

Maximum Laminating Width: 14.17"

(360mm) |

|

Maximum Laminating Thickness:

0-0.31" (8mm) |

|

Laminating Type: single or dual

sides |

|

Power Supply: 110 V/60Hz (One

side 1.1KW,two-sided 2.2KW) |

|

Laminating Temperature: 60-130

DEG C |

|

Machine temperature: 0-160 DEG C |

|

Operation Mode: Automatic or foot

switch control |

|

Warm Up Time: About 1 minutes |

|

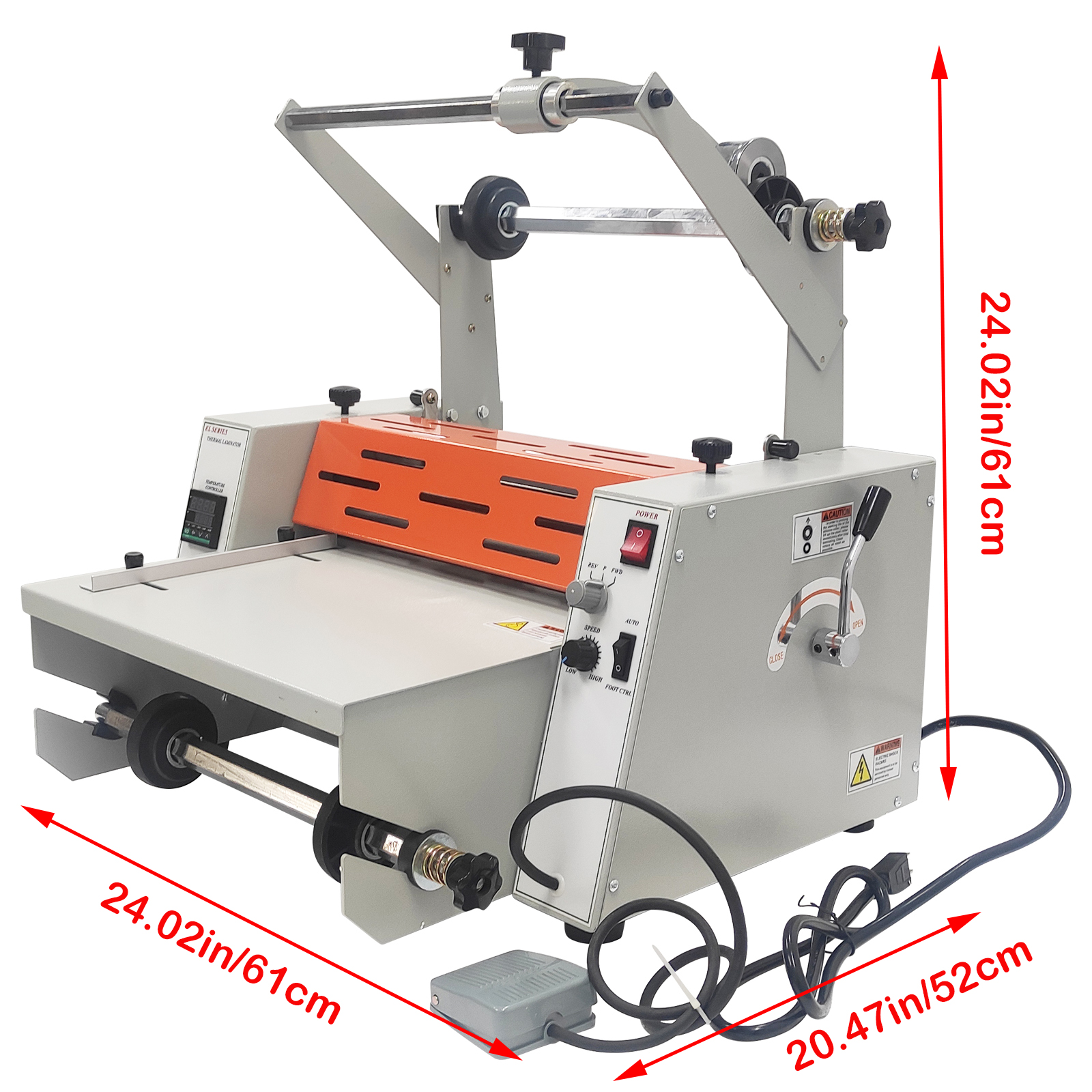

Machine Size:

24.02''x20.47''x24.02'' (61x52x61cm) |

|

Net Weight: 97lb (44kg) |

|

|

Notes |

|

1. Close

the protective cover during operation. Do not touch the heating rollers

to avoid scalds and other accidents.

2. Do not

touch the running parts during operation. Do not put the hands into the

machine.

3. Be careful—the cutter blade is shape. |

|

Operation Method |

|

1.

Unpack the package, ensure that all the accessories are intact, and

assemble all the accessories on the main machine. Install the film roll

and the material to be laminated in place.

2.

Connect the machine to the 110V power supply firmly and stably, turn on

the power switch, set the temperature through the temperature

controller, select the single side laminating or double side laminating

mode, select the forward or reverse rotation, adjust the speed, and

select the automatic or foot pedal control mode.

3.

After the temperature reaches the set value, start laminating.

4.

If the film roll is much wider than the material to be laminated, use

the slitting cutter to cut the film roll to obtain the appropriate size

and meet the accurate laminating requirement.

5.

After completing the laminating operation, turn off the power switch,

press the handle on the side wall to lift the laminating roller, and

clean the laminating machine thoroughly. |

|

Product

Features: |

|

1. The thermal laminator is of a

metal structure and is suitable for commercial and professional places. |

|

2. The top and bottom heating

rollers can be controlled separately to allow single-sided or dual-sided

lamination. |

|

3. The working speed can be

steplessly adjusted, the user can control the working process by

himself, and the humanized design is achieved. |

|

4. Foot/automatic control can be

conducted, the convenience is improved, and the user experience is

improved. |

|

5. The laminator supports 3''

cores and 1'' cores with width 12'' or less. |

|

6. The slitting cutter is matched

with the laminator and can cut the films which are required by the user, and

operation is facilitated. |

|

The temperature can be easily

controlled and adjusted, and single side and double side laminating can

be easily changed. |

|

The motion setting of

forward, reverse and pause can be easily switched, the foot switch

control and automatic control can be selected by the user, operation is

easier, and convenience is improved. |

|

|

|

|

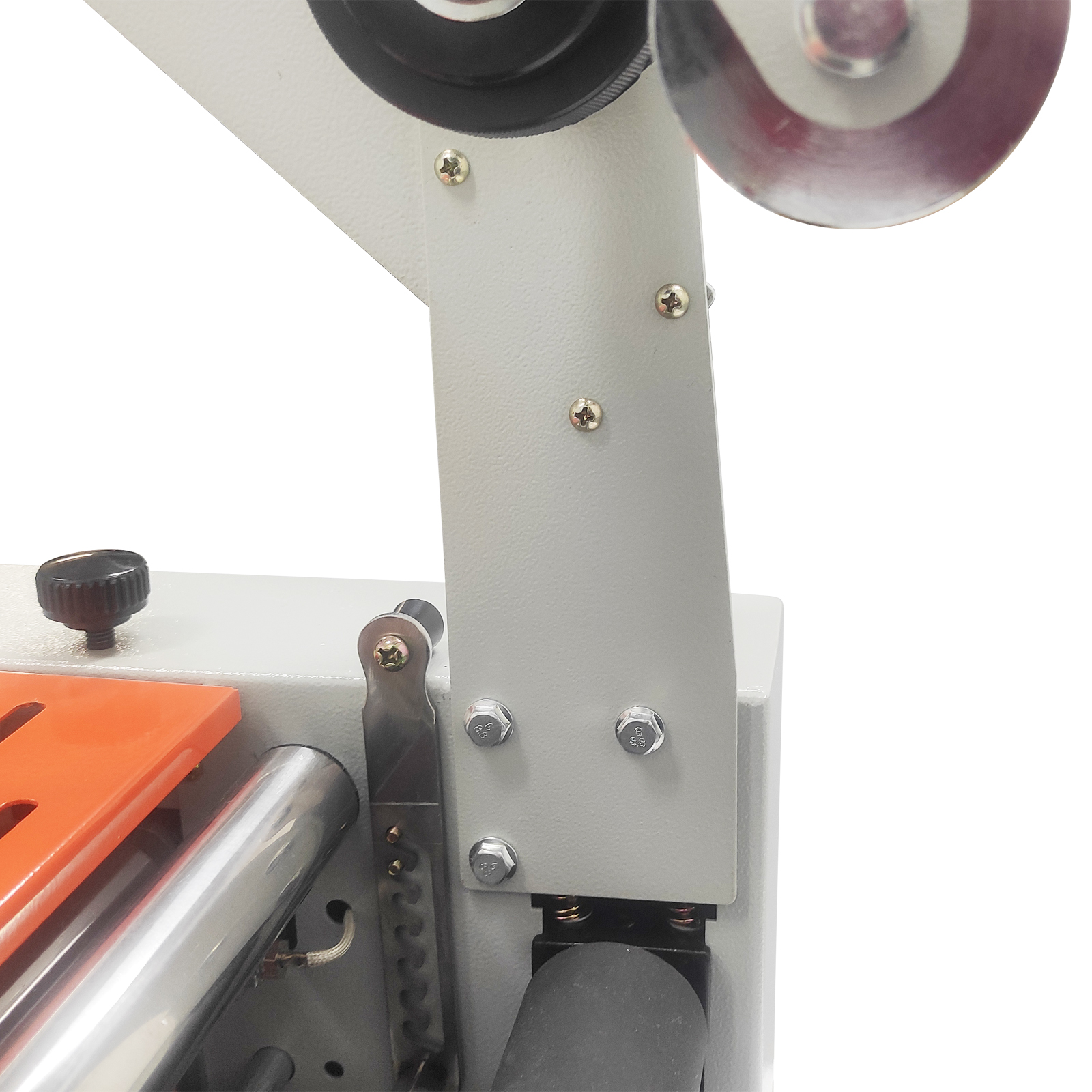

The slitting cutter can be

installed and adjusted as required, the films required by the user can

be cut by the slitting cutter, the residual films are left on the steel

roller, and the user can obtain the

proper film as needed. |

|

Installation

Tips: |

|

In the installation process of

accessories, the supporting plates on the two sides need to be installed

on the inner sides of the control platforms on the two sides through

screws, and the screws need to penetrate through the supporting plates

to be fixed to the control platforms. |

|

|

|

|

|

Item Number(122139): 1 x 110V Steel Roller

Thermal Laminator With Slitting Cutter and Accessories |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |